Fire Performance Cables

Prysmian Fire Performance (FP) Cables

Reliability at its core

The FP cable range is the result of almost 50 years of continuous development of cables for fire alarms, emergency lighting, life safety and fire fighting systems. Our fire performance cables are specifically designed to maintain circuit integrity and continue to work for a specific time under defined conditions of 30, 60, or 120 minutes. Our cables not only help save lives in a fire, but also provide greater property protection.

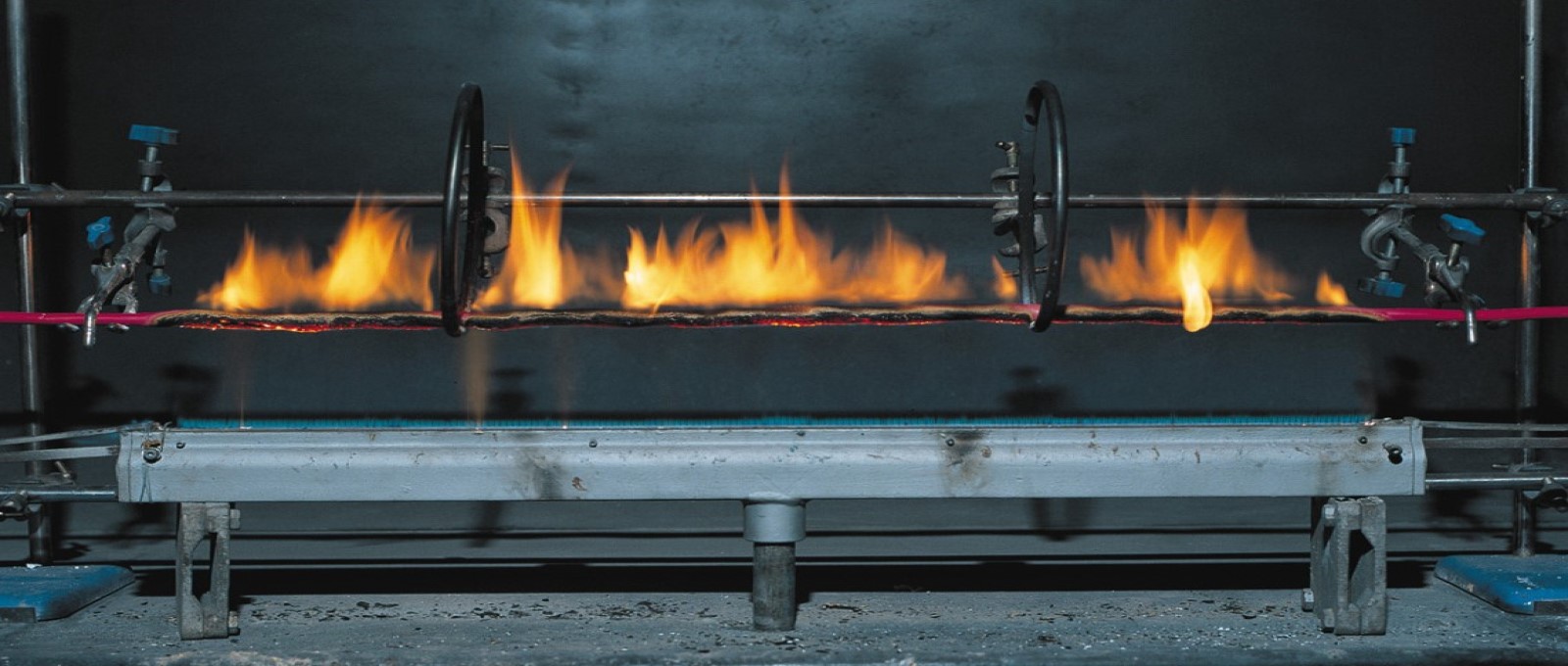

Prysmian FP cables are manufactured, tested and certified to a range of tests that assess circuit integrity in the event of fire to help save lives and property. Common building applications require minimum 30-minute flame tests with simultaneous impact and water spray, whereas large and complex buildings require a higher temperature flame for longer, 120 minutes, with more onerous impact and water tests.

Specify the engineers choice

Prysmian has been researching and developing high-quality, efficient fire performance cables for decades. This is even before British Standards for fire resistance became available. Prysmian Group can share that expertise and understanding through our seminars, find more here.

Our fire testing lab at Eastleigh conducts over 1,500 tests a year to quality check and perfect existing and new cable. When we test our fire performance cables, we test many elements including: fire resistance, spread of flame and smoke emission. We aim to develop better cables that help save lives and provide greater property protection. FP is the original, easy to install and fully compliant range of fire resistant cables approved by engineers, installers and regulators.

The FP cable range

Prysmian offers an extensive range of independently tested and certified fire resistant cables. Our FP range meets the critical installation and performance criteria, delivering the highest possible quality standard.FP cables manufactured by Prysmian are designed to meet the requirements of the relevant fire tests.

'Standard' fire resistant cables are required to achieve at least 30 minutes circuit integrity when tested in accordance with BS EN 50200 AND also to BS EN 50200 ANNEX E. 'Enhanced' fire resistant cables are required to achieve at least 120 minutes when tested to BS EN 50200 AND also BS 8434-2. The Prysmian fire performance cable range includes FP100, FP200 GOLD, FP400, FP PLUS and FP600s. Discover more about our products below, or visit our product page for the full range.

Discover the FP cable range

Power your success

Contact us

Select contacts by department